Use cases in Manufacturing

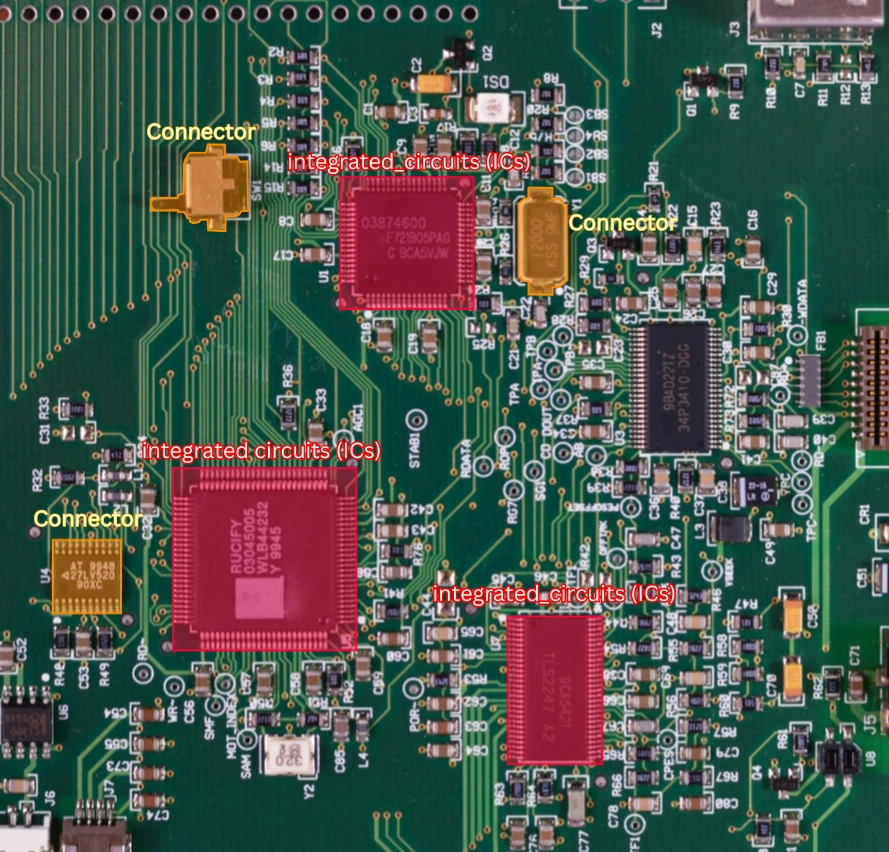

Efficient Product Assembly Monitoring and Optimization

Our intelligent product assembly solution streamlines manufacturing processes by monitoring assembly lines in real-time, ensuring each component is correctly positioned and assembled to quality standards. Using AI and sensor technology, it identifies any discrepancies or assembly errors, allowing for immediate corrective action and reducing production downtime. This system improves efficiency, boosts product consistency, and enhances overall productivity, making it ideal for manufacturers seeking to optimize operations and deliver high-quality products with minimal waste.

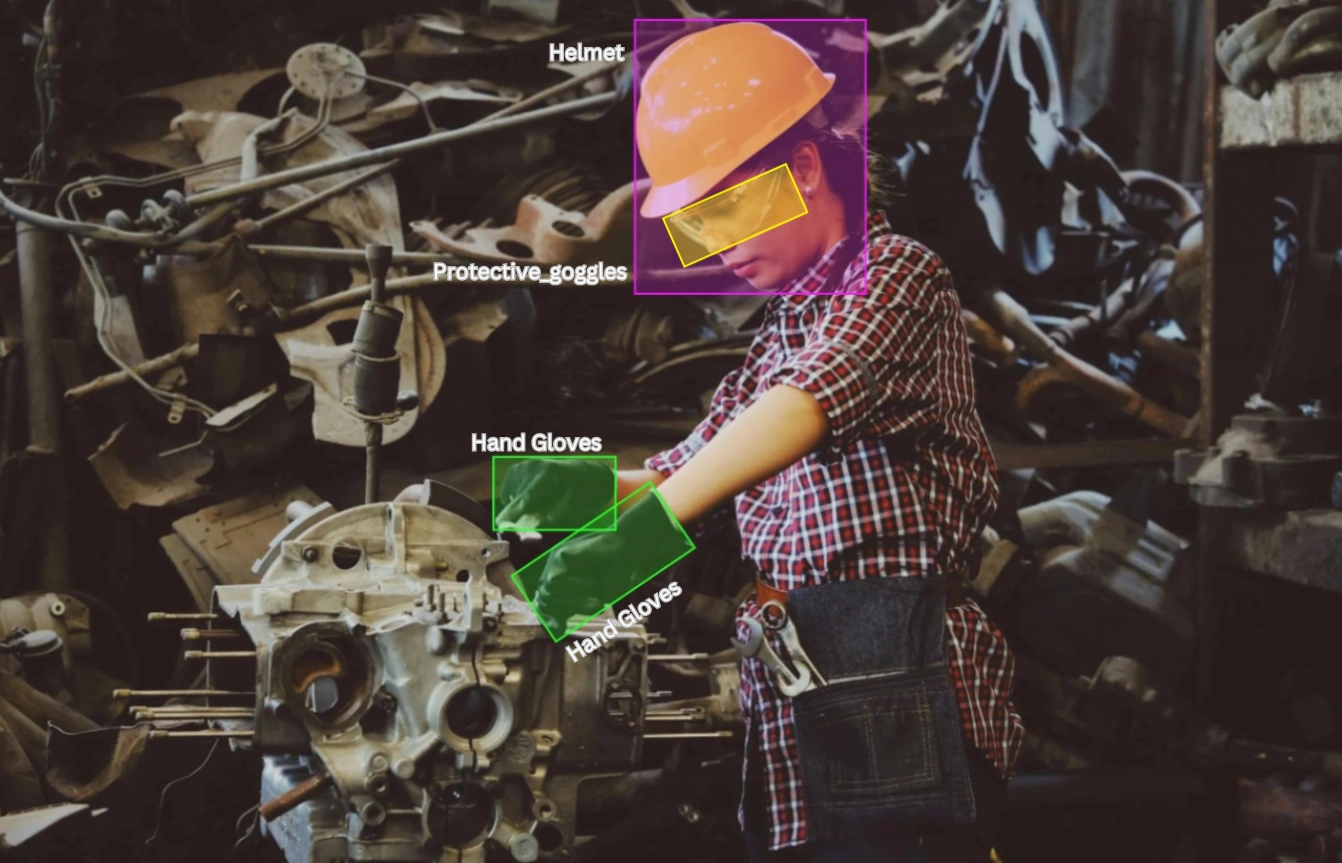

Safety Gear Detection and Alerts for Industrial Worker Protection

Our safety gear detection system enhances workplace safety by ensuring that workers are equipped with essential protective gear, like security masks, helmets, and gloves. Using advanced image recognition and sensors, the system automatically monitors if safety equipment is being worn and alerts management if any required gear is missing. This proactive approach not only protects workers from potential hazards but also helps companies comply with safety standards and regulations, reducing accident rates and creating a safer, more compliant industrial environment.

Real-Time Product Inventory Tracking and Management

Our real-time product inventory detection system enables precise tracking of inventory levels across the manufacturing process. Utilizing RFID, barcodes, and AI-driven analytics, it monitors stock levels, records movement, and provides alerts for replenishment needs. This system reduces stockouts, prevents overstocking, and ensures that materials are always available when needed, resulting in efficient workflow and reduced costs. Ideal for large-scale manufacturing facilities, it empowers businesses to optimize inventory management and support uninterrupted production.